Label applicators

Label applicators

Automation, covering both the printing itself and the entire labeling process, can be used at various levels of production. Print&Apply philosophy applies to various types of devices. All of them are characterized not only by high efficiency, but also ease of use and reliability. As IBCS Poland, we are the only representatives of Cobalt in Poland, a British manufacturer that produces automatic label applicators. We carry out the full process of integrating the complete device in the customer’s environment.

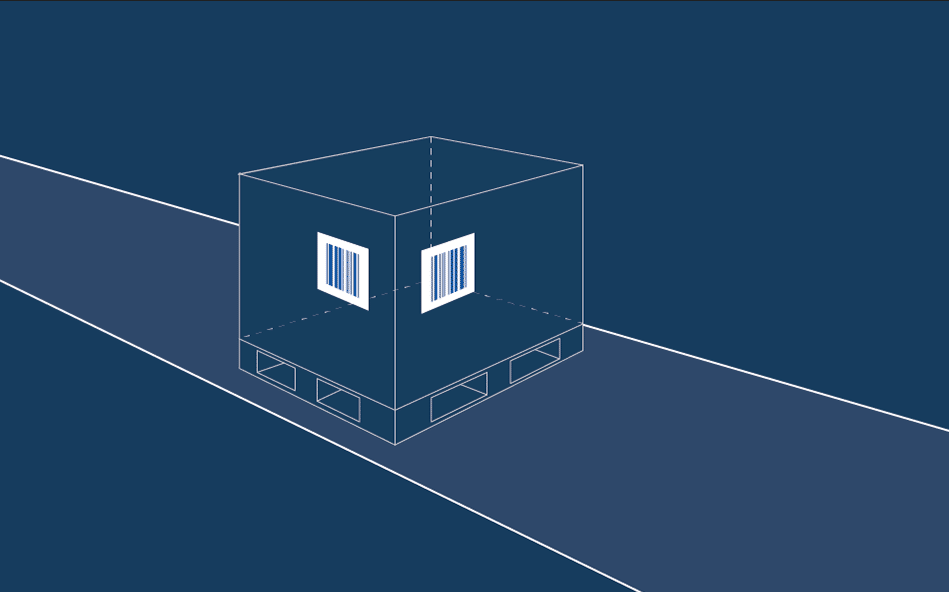

Nexus 20 Dual-Side Pallet

Nexus 20 Dual-Side is an efficient solution for applying two labels up to A5 size to both sides of a pallet without stopping the process, thanks to which the fast throughput enables the service of multiple production lines, concentrating the collection of finished pallets at fewer points and minimizing the need for wrappers and other applicators, while additional readers during printing ensure label compliance verification.

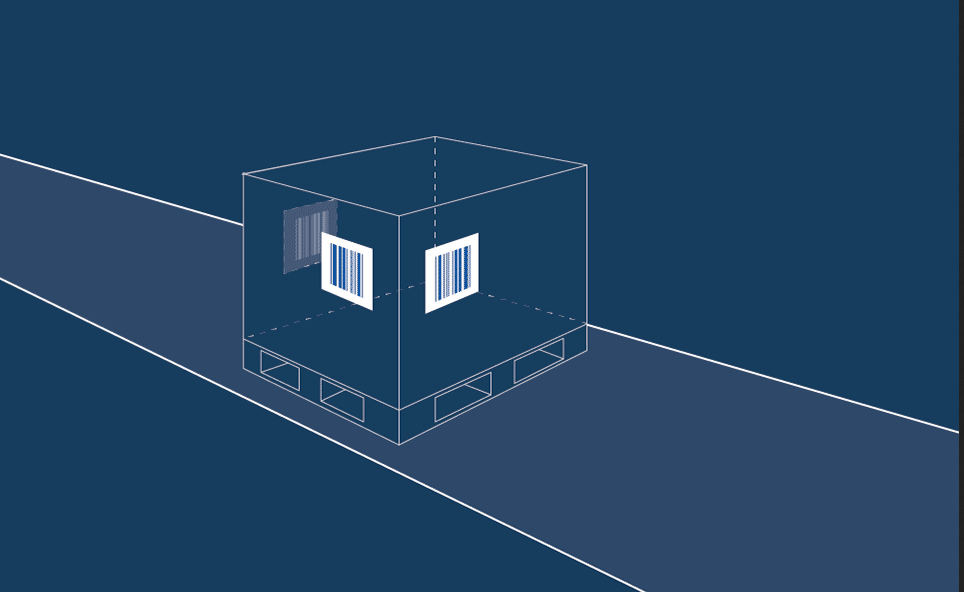

Nexus 20 Three Side Pallet

Nexus 20 Three Side Pallet is an intelligent system for applying labels on three opposite sides of a pallet, ideal for flexible pallet labelling and supporting warehouse operations by printing and applying e.g. A5 SSCC labels without the need to rotate the pallet, while ensuring validation and checking of the correctness of the data on the label.

Nexus 20 Dual Action Case

The NEXUS 20 Dual Action provides customers with incredible flexibility, enabling real-time labeling from the front, side, or front and side, with the ability to switch between HMI applications or optional recipe-based systems for even greater adaptability

Nexus 20 High Speed Linear

Nexus 20 High Speed Linear is a high-speed linear applicator that provides peace of mind in production management thanks to guaranteed barcode verification, applying labels at an impressive speed of 80 packages per minute, ideal for labeling packages, shrink-wrapped products, allowing each barcode to be verified and assessed for quality, allowing only good labels to be used in the further process.

Nexus Drum

Nexus Drum applicator can be used to apply labels to plastic canisters, cylindrical containers and other similar packaging. It can print multiple labels and apply them quickly. It is ideal for applying large GHS labels to curved surfaces.

NEXUS 20 Combi

A typical use case for NEXUS 20 Combi is food and beverage manufacturers who need to print and apply variable data (ingredients, dates, batch information) on one side of their primary product packaging, but also need to apply a full-colour consumer-facing detail – a corresponding label – on the other side.

Nexus Contact

Nexus Contact applicator provides fast, flexible label application. Allows you to synchronize the speed of label application with the products they are applied to. For use on high-speed lines. Low maintenance and a robust design provide an excellent return on investment.

Nexus Pivot

Nexus Pivot is a high-speed front-of-pack label applicator that delivers labeling speeds of up to 80 packages per minute.

Cobalt Continuous Operation Systems

Cobalt Continuous Operation Systems solution is designed to eliminate downtime related to label replenishment or system maintenance. In the long run, it helps avoid unnecessary disruptions and lost revenue. Cobalt Continuous Operation Systems is a dynamic labeling system where two or three machines work in rotation and maintain the lines.

SATO printing module

Zebra or SATO printing module for applicators is available from IBCS Poland. You can choose from solutions with 203, 305 or even 609 dpi resolution. Modules can be delivered with manufacturer warranty packages (Zebra, Sato) or can be covered by an IBCS service contract together with other printers or mobile terminals.

RFID applicator

We can equip the Nexus Cobalt print and apply devices with Zebra or SATO RFID programming modules. We provide a solution for applying small RFID labels, e.g. 40 x 70 mm, carton labels, e.g. 100 x 150 mm or A5 pallet labels (148 x 210 mm) with an RFID tag.